VULCAN OUTLAW 195 Engine-Driven Stick Welder with CO SECURE Technology

- This VULCAN® OUTLAW™ Engine-Driven Stick Welder uses inverter technology to deliver 195 amps max. DC welding output for smooth, high-quality welds.

- Powerful 13 HP, 420cc PREDATOR® engine for reliable performance

- 6.5 hours runtime at 50% load

- CO SECURE® technology automatically shuts down the engine for safety when harmful levels of carbon monoxide are detected

- Electric start with manual backup, 12V battery included

- Digital display for fast, easy weld setups

- Includes 12 in. wheel kit for easy jobsite portability

- Thermal overload protection extends welder life

- Includes both 120V and 240V outlets

- Overweight Item subject to $129.99 additional Freight Charge

$1799.99

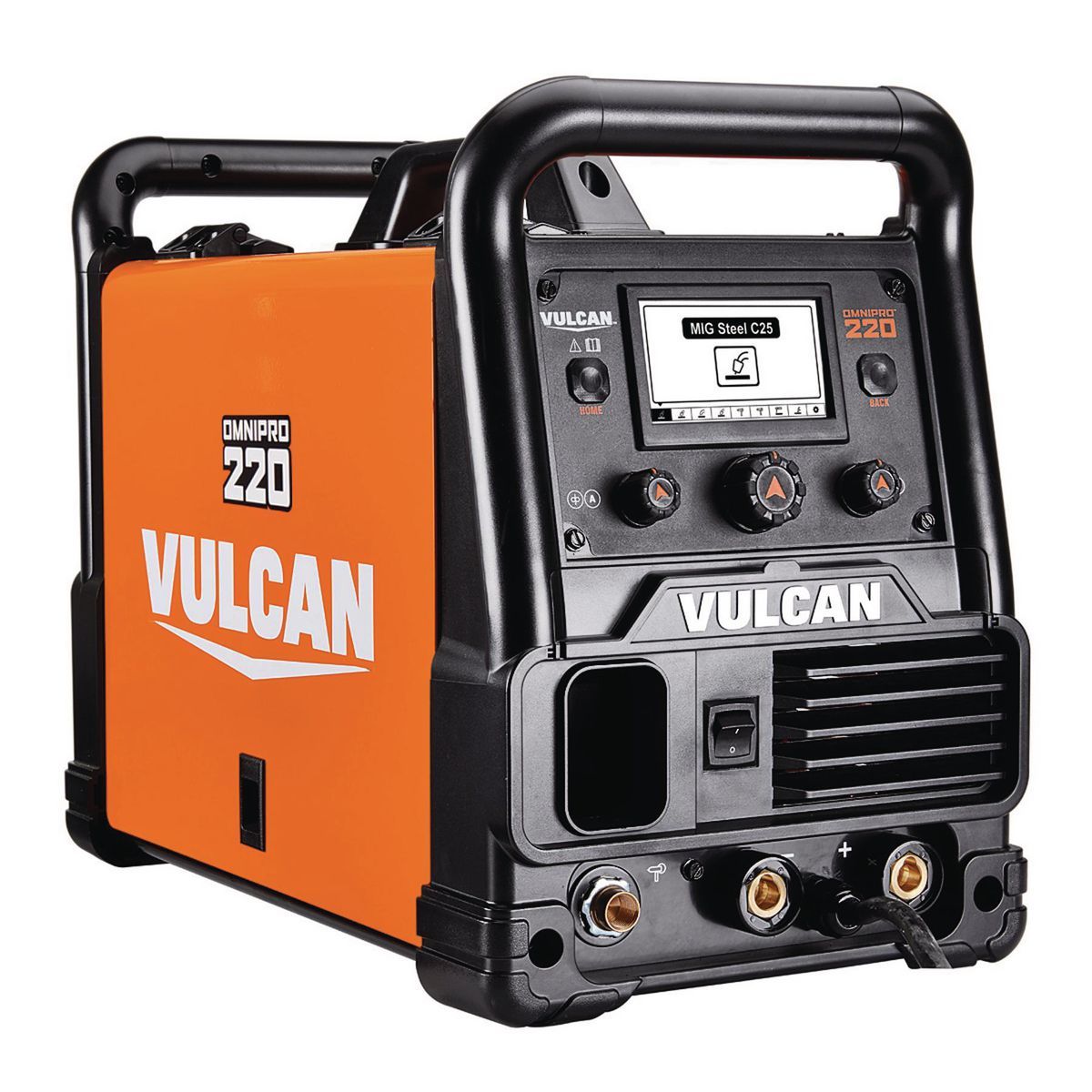

VULCAN OMNIPRO 220 Industrial Multiprocess Welder with 120/240V Input

- The OMNIPRO™ 220 Industrial Multiprocess Welder is a top of the line multiprocess welder that is lightweight, powerful and intuitive. Just set material thickness, process type, and the rod or wire diameter, and you’re ready to weld. Versatile and rugged, this high output multiprocess welder takes your welding to the next level whether it’s MIG, Stick (DC), TIG (DC), or Flux-core welding. This powerful machine is ready for any job in the shop or jobsite. Weld a wide range of materials with a fast, easy set-up and full color display. WELD ON THE JOB, PLUG IN ANYWHERE – Plug into any power supply with the included power cables. SYNERGIC SETTINGS – The welder does most of the work. The user-friendly interface makes set-up a snap with easy to access advanced options. HIGH OUTPUT – The OMNIPRO™ 220 gives you the power to tackle the biggest jobs with ease and confidence.

- True multiprocess power source for MIG, Flux-core, DC TIG and DC Stick welding

- 132 pre-loaded welding programs for easy setup

- Exclusive memory feature for instant recall of critical welder settings

- Best-in-class 4.3 in. LCD display for process selection and advanced controls

- Weighs only 49.00 lb. – ideal for shop or field use

- Dual voltage technology capable of 120V or 240V input

- Spool gun ready – no adapter required

- Industrial grade cast aluminum drive system

- Inverter technology for highest quality output and maximum efficiency

- 120V and 240V power cords included

$1099.99

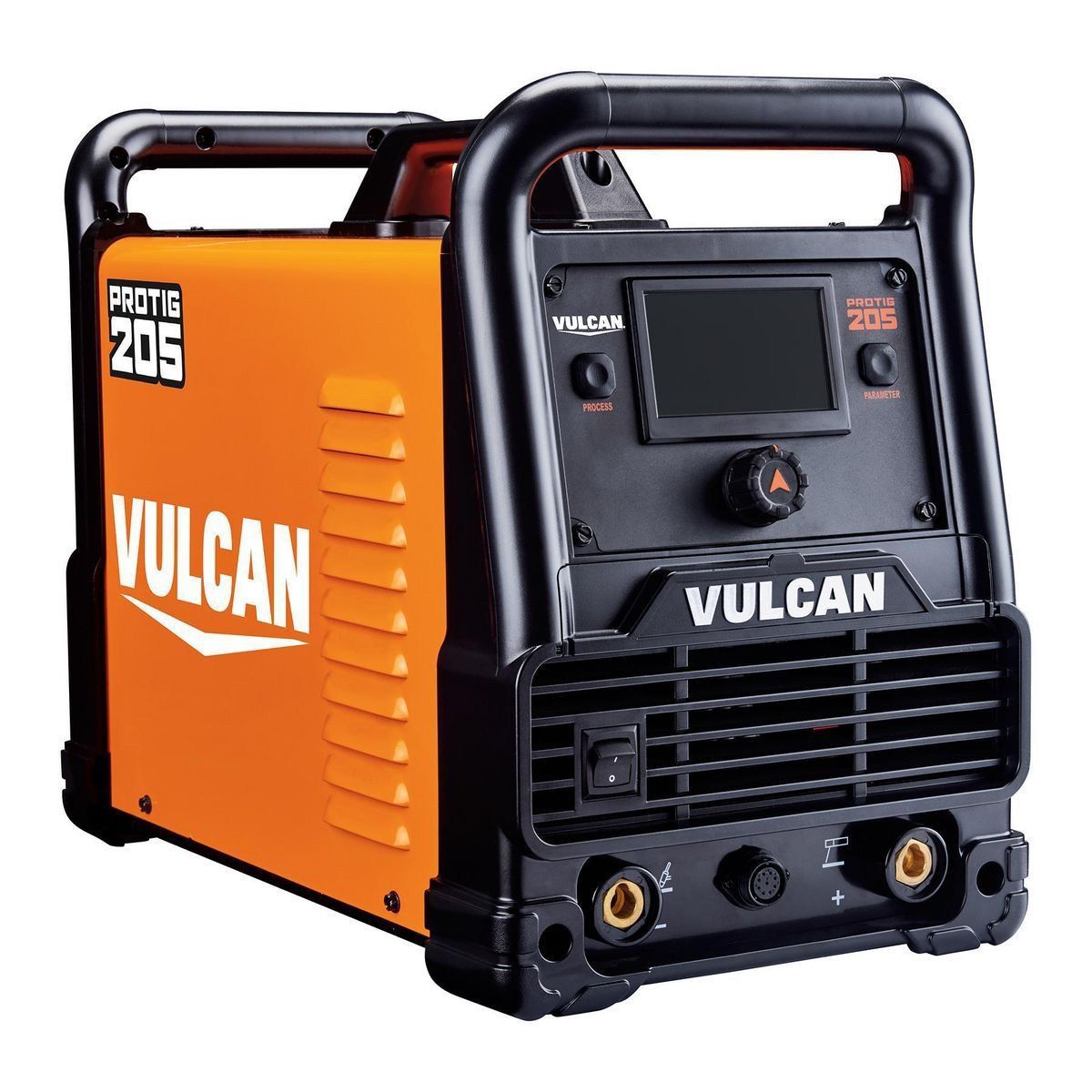

VULCAN ProTIG™ 205 Industrial Welder with 120/240V Input

- The VULCAN® ProTig 205 is the ultimate tool for the professional or hobbyist welder. Featuring a solid 205-amp of AC/DC TIG welding power, it can weld any metal up to 5/16 in. in a single pass. It can also deliver solid stick welding performance with 175-amp of power, enough to handle most 1/8 in. electrodes. Inverter technology allows the ProTig 205 to stay lightweight while also delivering the highest quality output at maximum efficiency. The 53 lb. ProTig 205 is versatile enough to use in any environment, with dual voltage technology that allows you to use the unit on 120-volts in areas that don’t provide 240-volt electricity and still have enough power to get the job done. Pre- and post-flow control allow the operator to adjust the amount of gas coverage for their application. AC Balance and AC Frequency give the operator ultimate control over the focus and penetration of their AC TIG welding arc. This welder comes with nearly everything inside the box necessary to start TIG welding: foot pedal, air-cooled TIG torch, stick electrode holder with cable, work clamp with cable, regulator, and starter consumable kit are included as part of the package. Just add gas, your favorite filler rods and you are ready to complete your project.

- Advanced features with simple interface

- Outstanding TIG aluminum performance

- TIG and DC stick from a single power source for ultimate versatility

- High frequency arc starting for ultimate arc quality

- Built-in pulsing for increased travel speeds and minimized heat distortion

- Weighs only 53 lb. – ideal for shop or field use

- Dual voltage technology capable of 120V or 240V input

- Inverter technology for highest quality output and maximum efficiency

- 120Vv and 240V power cords are included

$1099.99

Welding is an invaluable skill for auto repair, metal fabrication, sculpture, and more. While there are many types of welders available, stick welders remain a popular choice for their versatility and ease of use. The Vulcan stick welder is a top brand known for durability and consistent welds.

If you’re considering buying a Vulcan stick welder, this guide covers everything you need to know, from what stick welders do to where to find the best deals. Let’s get started!

What Is a Stick Welder Used For?

Stick welders, also known as arc welders, use an electric arc between a consumable stick electrode and your workpiece to melt metal and create welds. The stick electrode consists of a thin wire coated in flux, a compound that helps form a protective gas shield and slag to prevent oxidation.

As the stick electrode melts, it deposits filler metal from the wire and flux onto your weld joint. This makes stick welding versatile for repair jobs and projects with metals like mild steel, stainless steel, cast iron and hard surfacing alloys. Common applications include:

- Structural fabrication

- Pipe welding

- Farm and machinery repair

- Automotive repair

- Sculpture and metal art

- Home DIY projects

Stick welding excels at outdoor jobs and positions where the welder can’t see the weld line directly since the arc is highly visible. The handheld torch and portable power source also make stick welders a practical choice for on-site welding.

How to Set Up a Vulcan Stick Welder

Setting up a Vulcan welder only takes a few steps:

- Select an appropriate power source. Vulcan welders can run on 120V or 240V power. Choose based on your electrical setup and welding needs.

- Plug in the power cord and flip the power switch on (markings may vary by model). The fan should start running to prevent overheating.

- Install an electrode holder with an appropriate electrode for your material and weld settings. Twist to secure.

- Adjust the amperage with the dial based on your electrode size and type according to the welder manual. This controls penetration.

- Connect the work clamp to your workpiece, ensuring a solid metal-to-metal contact area.

- Align your electrode vertically on the weld joint at a 10-15 degree drag angle.

- Flip down your welding helmet and you’re ready to lay down your first weld bead!

That’s really all there is to it. Always refer to your specific model’s manual for proper set up and duty cycle. Now let’s look at why welders recommend Vulcan.

Why Choose a Vulcan Stick Welder?

There are many stick welders to choose from, but the Vulcan brand stands out for reliability, performance, and value. Here are some of the reasons why Vulcan earns top marks from welders:

- Trusted American brand – Vulcan has manufactured welders in the USA for over 80 years. Their reputation for solid quality has stood the test of time.

- High duty cycle – Duty cycle is the percentage of time in a 10 minute window you can safely weld at max power. Vulcan excels here with up to 60% duty cycle on some models. This improves productivity.

- Thermal overload protection – Vulcan welders prevent dangerous overheating with automatic thermal shutoff. You don’t have to worry about accidentally ruining your machine.

- Large amperage range – Vulcan welders can fine tune from around 20 to 200+ amps depending on the model. This versatility handles everything from thin sheet metal to thick steel.

- Sturdy all-metal case – The solid metal construction protects components and makes Vulcan welders highly durable for workshop use.

- Budget-friendly price – For the performance, Vulcan welders are very competitively priced compared to other brands. Great value!

Overall, Vulcan offers workhorse welder performance without breaking the bank. Let’s look closer at what to expect with a Vulcan stick welder.

Key Features of the Vulcan Stick Welder

Vulcan stick welders come in different amperages and sizes, but they share many of the same core features that make them so robust:

- All-copper transformer – The heavy copper windings efficiently produce maximum usable amperage and stand up to high temps.

- Sturdy electrode holder – Industrial-grade electrode holders withstand high heat. Ergonomic comfort grip allows precise electrode control.

- 10-foot electrode and work cables – Long, flexible cables provide ample working room from your power source. Reduce tripping hazards.

- Front mounted controls – Conveniently adjust amperage and power right on the front of the machine. Improves ease of use.

- Carry handle – Makes transporting your portable Vulcan to worksites easy with a sturdy top handle.

- Overload protection – Protects the welder from excessive duty cycles. Auto-resets when cooled for safety.

- Quick connects – Secure twist-lock connections provide positive electrical contact to prevent arc outage.

- Thermal overload light – Alerts you if the machine overheats and shuts off so you don’t mistakenly think it’s broken.

- Fan cooling – Directs air over internal components to reduce heat buildup and improve duty cycle.

Together, these features enable Vulcan welders to deliver top notch welding capabilities while holding up to years of use. Now let’s look at pricing.

What Does a Vulcan Stick Welder Cost?

Vulcan stick welders range from about $150 to $500 depending on the model’s amperage capacity and features. Here are some example prices:

- Vulcan 140 – $159 – Great starter welder for light home/auto projects. Handles up to 1/8” steel.

- Vulcan OmniPro 220 – $339 – All-around workshop welder. Welds up to 3/8” steel. 60% duty cycle.

- Vulcan Nomad 185 – $499 – Portable welder packs power. Welds up to 5/16” steel. Weighs under 40 lbs.

Keep in mind you’ll need safety gear like a welding helmet, gloves, etc. which cost extra. Also budget for electrodes, usually $10-20 for a box.

What about deals? Vulcan welders often go on sale around holidays and during retailer clearance events. Check for coupons too – you can sometimes stack savings for the best price.

Where to Buy a Vulcan Stick Welder

You’ll typically find the best Vulcan welder prices at major retailers like:

- Home Depot – Large selection of Vulcan models both online and in-store. Free shipping on most models.

- Northern Tool – Authorized Vulcan retailer with full product line available. Store pickup savings.

- Tractor Supply – Competitive pricing plus additional savings for Buy Online Pickup In Store.

- eBay – Good source for deals on new and used Vulcan welders from various sellers.

- Amazon – Fast free Prime shipping on select Vulcan models. Check seller ratings.

- Vulcan’s Website – Buy factory direct. Good for custom bundles with welding hoods, torches, and cables.

I suggest checking prices across a few sites as sales can vary. Also confirm the return policy in case you need to exchange a defective unit. Now let’s look at what you can weld.

What Metals Can the Vulcan Stick Welder Handle?

Vulcan stick welders can handle welding a wide range of metals thanks to the versatile nature of stick welding. Here are some of the most common projects:

- Mild steel – Low carbon steel is the easiest to weld. Great for structural frames, trailers, tools, etc. Good match for fast-freeze E6010 electrodes.

- Stainless steel – More difficult due to slow solidification. Use E308L or E316L rods. Preheating helps.

- Cast iron – Prone to cracking without proper preheat and E309L electrodes. Key for auto repair and machinery.

- Aluminum – Requires AC stick welders and special aluminum electrodes. Some Vulcans offer AC/DC capability.

- Hard surfacing alloys – Builds up wear resistance on excavator buckets, bulldozer blades, truck beds, etc.

For thin metals under 1/8”, stick welding becomes challenging and requires lower amperage. For thickness over 3/8”, you’ll need 400+ amps. Upgrade to a heavy duty Vulcan model or use multiple passes.

Finally, stick welding excels at positions besides flat welding. You can weld vertical, overhead, and even upside down! The fluid molten puddle sticks well on inclined planes.

Who Is the Vulcan Stick Welder Good For?

Thanks to their versatility and affordable pricing, Vulcan stick welders suit a wide range of users:

- Beginners – Easy to set up and learn. Less sensitive to angle and speed than MIG welding.

- Farmers/mechanics – Rugged and portable for quick repairs. Doesn’t require gas like MIG or TIG.

- Fabricators – Provides penetration for structural joints. Higher deposition rate than TIG or gas welding.

- Sculptors – Allows freedom to weld abstract shapes. Bonus: reusability of stub electrode ends for fill.

- Home DIY warriors – An all-purpose welder for projects and repairs around the house, shop, or garage.

- Professionals – Commercial-grade performance at an affordable price point. Some pro welders keep a stick machine on hand as a backup.

- Small business owners – Economical option for maintenance of equipment and facilities. Lower upfront cost versus industrial welders.

The only folks I’d steer clear of a basic Vulcan are precision sheet metal workers since stick welding has a larger weld pool. But for most users, it’s a great fit.

Benefits of Using a Vulcan Stick Welder

Let’s recap the biggest advantages of buying a Vulcan arc welder:

- Value – You get exceptional performance for the price. Vulcan doesn’t cut corners.

- Durability – All-metal cases withstand years of use and drops. Many last decades.

- Quality welds – Smooth stable arc allows precise puddle control for solid welds.

- Thicker metals – Higher amps provide penetration lacking on small 110V consumer welders.

- Portability – Compact size and light weight makes for easy transport to jobsites and around the shop.

- Multi-process – Stick welding also opens the door to flux core, TIG (with torch add-on), and potentially AC aluminum.

- AC/DC – Some Vulcans provide AC capability for aluminum at a fraction of a dedicated aluminum welder.

- Made in USA – Vulcan supports American manufacturing jobs. Good customer service and parts availability.

For projects that require high-amperage portable welding, Vulcan delivers where budget welders fall short. That versatility makes it a worthwhile investment for amateurs through professionals.

How Does Vulcan Compare to Other Brands?

The biggest competitors to Vulcan in the stick welder market are Lincoln Electric, Miller, Forney, AHP, and Everlast. Here is how Vulcan typically stacks up:

- Lincoln Electric – Comparable quality but often costs $100+ more. Excellent for commercial use.

- Miller – The gold standard in welding but priced much higher. More suited to industrial settings.

- Forney – Good budget brand but doesn’t match Vulcan for durability and performance.

- AHP – Competitively priced like Vulcan but with a shorter track record. Good value.

- Everlast – Affordable prices but overseas manufacturing leads to more quality control issues.

- Eastwood – Decent small amp welders. Larger models don’t compare to Vulcan’s penetrative power.

Overall, Vulcan provides the best balance of price, performance and reliability in the under $500 range. Lincoln or Miller offer a modest bump in perfection for much higher cost.

Does Vulcan Offer Any Accessories?

One benefit of going with a widely popular brand like Vulcan is accessory availability. You can customize your welding setup for convenience. Here are some helpful Vulcan accessories:

- Remote foot amperage control – Hands-free way to adjust amperage while welding. Maintains proper arc length.

- Arc gouging torch kit – Converts machine for carbon arc gouging to remove metal fast. Useful for weld cleaning and prep.

- Welding cart – Secures cylinder and provides storage for gear. Easier than lugging equipment around piecemeal.

- Undercarriage – Allows wheeling the welder around the workspace smoothly. Beats carrying a heavy welder.

- Protective cover – Prevents dust and debris from accumulating on machine. Helpful for long-term storage.

- Stick electrode holder – Upgrade to heavy duty model for better comfort and cooling. Standard holders still good.

- Helmet and gloves bundle – Convenient all-in-one starter kit. Look for auto-darkening helmet option.

Accessories allow you to adapt your Vulcan welder to different situations. Keep them in mind down the road as needs arise.

Troubleshooting Vulcan Welder Problems

Vulcan welders are built to last decades with proper care. But issues can occasionally crop up, usually with quick fixes:

- Not powering on – Check cords/plugs, breakers/fuses, and selector switch position. Reset thermal protector if tripped.

- Weak arc – Switch to fresh electrode. Verify work clamp connection is tight on bare metal. Clean/replace terminals if corroded.

- Sticking electrodes – Increase amperage and/or switch to faster-freeze electrodes. Insufficient heat causes sticking.

- Porosity – Dry electrodes by baking to remove moisture. Check for drafts. Avoid excessively long arcs.

- Excess spatter – Reduce amperage. Ensure work angle is not too sharp. Wet electrodes can cause spatter.

- Weld cracking – Increase preheat on thick steel. Slow cooldown with insulation. Check electrode alignment.

If problems persist after basic steps, consult your manual. Vulcan also has an experienced US-based customer support team to help diagnose issues. Call or email them for troubleshooting advice before any extensive repairs.

What Is the Warranty on Vulcan Welders?

One advantage of buying from an established US brand is getting a generous factory warranty. Vulcan stick welders typically come with a 5 year warranty on parts and 3 years on electronics.

This covers defects in materials and manufacturing, aside from normal wear parts like electrodes and nozzles. Just register your welder online after purchase to activate coverage. Be sure to keep your receipt.

For problems during the warranty period, Vulcan will repair or replace defective components free of charge. This provides great peace of mind that your sizable welder investment is protected. If purchasing used, check if any warranty remains transferable.

Maintaining Your Vulcan Stick Welder

With proper maintenance, your Vulcan welder will deliver decades of use. Follow these tips:

- Remove dust/dirt – Periodically blow out the interior with compressed air to prevent component clogging.

- Inspect connections – Check for any loose or damaged cables/cords that could disrupt power delivery.

- Clean terminals – Prevent voltage drop by cleaning oxidation off terminals with a wire brush or sandpaper.

- Check ground clamp – Ensure the teeth are sharp for optimal electrical contact through paint and rust.

- Replace electrodes – Swap out electrodes that get wet or damaged. Re-dry moist electrodes in an oven.

- Store indoors – Keep welder in a clean, dry location to avoid moisture and dust accumulation when not in use.

- Follow duty cycle – Allow sufficient cool-down time between welding periods. Don’t exceed max duty cycle time.

Taking the time for proper care and storage will keep your Vulcan stick welder running optimally for years beyond the warranty period.

Where Should You Use a Vulcan Stick Welder?

Vulcan welders require proper power setup and ventilation to operate safely. Here are some usage guidelines:

- Near an outlet – Extension cords reduce available amperage. But if needed, use 12 or 10 gauge cord for 15 and 20 amp welders.

- Well-ventilated – Use outdoors or near open doors/windows. Avoid tight confined spaces due to smoke and gases.

- Away from flammables – Place welder safely away from fuel, paint, chemicals, etc. Have a fire extinguisher on hand.

- Not wet areas – Only operate welder in dry conditions. Moisture creates electrocution and short circuit risk.

- On a level surface – Reduces risk of welder tipping over while in use or being moved.

- Ambient above 0°F/-18°C – Vulcan specifies minimum safe operating temps. Below this can damage components.

- With eye protection – Use a welding helmet or shaded glasses. Don’t look directly at the arc even briefly due to UV rays.

Choosing the right welding location optimizes safety and performance. Consult your Vulcan manual if planning to operate at high altitude, humidity, or temperature extremes.

How to Operate a Vulcan Stick Welder Safely

Welding presents potential hazards from heat, voltage, and fumes. Following some basic precautions will allow safe Vulcan operation:

- Disconnect power – Unplug machine before moving or making adjustments to reduce shock risk.

- Insulated gloves – Ensure gloves are dry and undamaged. Replace leather gloves periodically.

- Non-flammable clothes – Wear cotton or leather to avoid burns. No synthetics which can melt and stick.

- Proper eye protection – Use the right lens shade for your amperage to prevent eye damage from the arc.

- Welder’s jacket/apron – Prevent sparks hitting your body and clothes igniting.

- Ventilated area – Avoid breathing welding fumes by keeping your head out of the smoke plume. Use portable ventilation when possible.

- Firm footing – Maintain good balance to prevent contacting the live electrode or workpiece. Avoid wet floors.

- Coiled cables – Prevent tripping by keeping excess cable out of walkways. Don’t wrap cables around yourself.

- Reduce distractions – Remain alert during welding. Double check amperage setting before striking the arc.

With training and vigilance, you can manage the inherent risks in welding. An investment in proper safety gear will repay itself many times over in the long run.

What Is the Duty Cycle of a Vulcan Welder?

The duty cycle defines how long you can safely weld at a machine’s maximum amperage over a 10 minute window. For example, a 20% duty cycle at 150 amps means you can weld for 2 minutes out of every 10 at that power.

Vulcan duty cycles typically range from 20% on small models up to 60% on heavy welders. This exceeds cheaper brands and allows longer continuous welding.

Follow your machine’s amperage and duty cycle ratings to prevent excessive heating and automatic thermal shutoff. If the machine does overheat, give it 15-30 minutes to cool before resuming welding.

With moderate use below max amps and proper ventilation, Vulcan welders easily support hobby through moderate professional use. Larger industrial models offer 100% duty cycle for continuous work.

Reviews of the Vulcan Stick Welder

With decades in business and thousands of welders sold, there are plenty of Vulcan owners who’ve put them to the test. Here are some thoughts from real-world customer reviews:

“I’m a farmer welding galvanized stock tanks and trailers all the time. This Vulcan 205 has been amazing for the price. Way better than the Lincoln tombstone I borrowed from a neighbor.”

“As a metal sculpture artist, I need consistent welds on weird angles. I get great penetration on 1/4″ steel without blowing through thinner sections. Lots of control with the Vulcan 140.”

“I fix heavy equipment and need a portable welder built to last in tough conditions. My old Vulcan 220 just won’t die after 15 years of hard use and abuse.”

“For automotive work you can’t beat the value of these Vulcan welders. I upgraded from a 90 amp Harbor Freight special and it’s night and day for welding 3/16″ exhaust tubing.”

“I learned stick welding on my Vulcan Omnipro 220 at home. Now I use it to make custom railings, furniture, and art pieces in my garage shop. Does everything I need.”

The common thread is Vulcan machines standing up to regular use across trades – farm, industrial, automotive, fabrication, and art. Welders praise the easy arc and penetration on thicker steel combined with light portable size.

How Does Learning on a Vulcan Translate to Other Welders?

The skills you gain from a Vulcan stick welder transfer well:

- MIG welding – Same principles of arc length, travel angle, and puddle control apply. Easier wire feed reduces skills barrier.

- TIG welding – More challenging than stick but excellent foundation of hand-eye coordination under the hood and edge preparation.

- Engine driven welders – Portable skillset directly applies. Generator power eliminates finding outlets.

- Plasma cutting – Cutting torch utilizes similar wrist motions and progression direction as stick welding.

- Spot welding – Shared ability to keep arc length consistent as parts shift. Hand tools skills also transfer over.

- Oxy-fuel welding – Fundamentals like edge preparation, joint fit up, and filler rod manipulation carry over.

While each process has unique techniques, stick welding develops core competencies useful for welding across methods. It’s great experience before investing in more expensive industrial welders.

How to Improve Your Skills With a Vulcan Stick Welder

Here are some tips to hone your welding technique with a Vulcan:

- Practice all positions – Don’t just stick to flat welding. Develop vertical, overhead, and downhill skills.

- Take a welding class – Local trade schools and community colleges offer affordable hands-on instruction.

- Read welding books/guides – Expand your knowledge of proper techniques, electrode selection, and applications.

- Watch online videos – Free welding tutorials on YouTube are incredibly helpful for visual learners.

- Join online forums – Get feedback by sharing project pictures and asking questions on communities like WeldingWeb.

- Check your beads – Examine each weld profile and look for ways to improve consistency. Strive for perfection.

- Experiment with settings – Push your skills by trying new electrodes and amperages. See what works best for different materials.

Don’t get discouraged at the start – stick welding takes regular practice. Over time you’ll develop “muscle memory” and unlock this rewarding skill.

Where to Store a Vulcan Welder for Protection

Proper storage preserves your Vulcan stick welder between jobs:

- Dry place – Prevent rust by storing indoors in a shed, garage, or shop if possible. Avoid direct exposure to rain.

- Room temperature – Keep away from freezing temps and excessive heat that could damage electronic components.

- Power off – Disconnect power cord and switch off machine before storage to avoid accidental arcing.

- Covered – Use a welding blanket or dedicated cover to reduce dust and debris accumulating on the machine.

- Upright – Store welder standing up instead of laying down to minimize stress on components from the welder’s own weight.

- Clean – Wipe down exterior and clean any spatter off torch heads before storage. Promotes longevity.

- Cables coiled – Wrap up cables neatly to prevent kinking or tangled damage. Avoid tight bends.

- Electrodes removed – Take electrodes out of torch for safe keeping. Store open packages in sealed containers.

A little care in storage goes a long way in preserving full welding performance and extending the impressive lifespan of your Vulcan welder.

Ready to Buy a Vulcan Stick Welder?

I hope this guide gave you all the information needed to choose the right Vulcan welder for your needs and wield it like a pro. With Vulcan’s reputation for quality and their wide model selection, you’re sure to find the perfect match.

Ready to start laying down some beads? Pick an improvement project and let the sparks fly! Remember to invest in some proper safety gear, then it’s time to put your new Vulcan stick welder to work. Your next great creation is waiting.