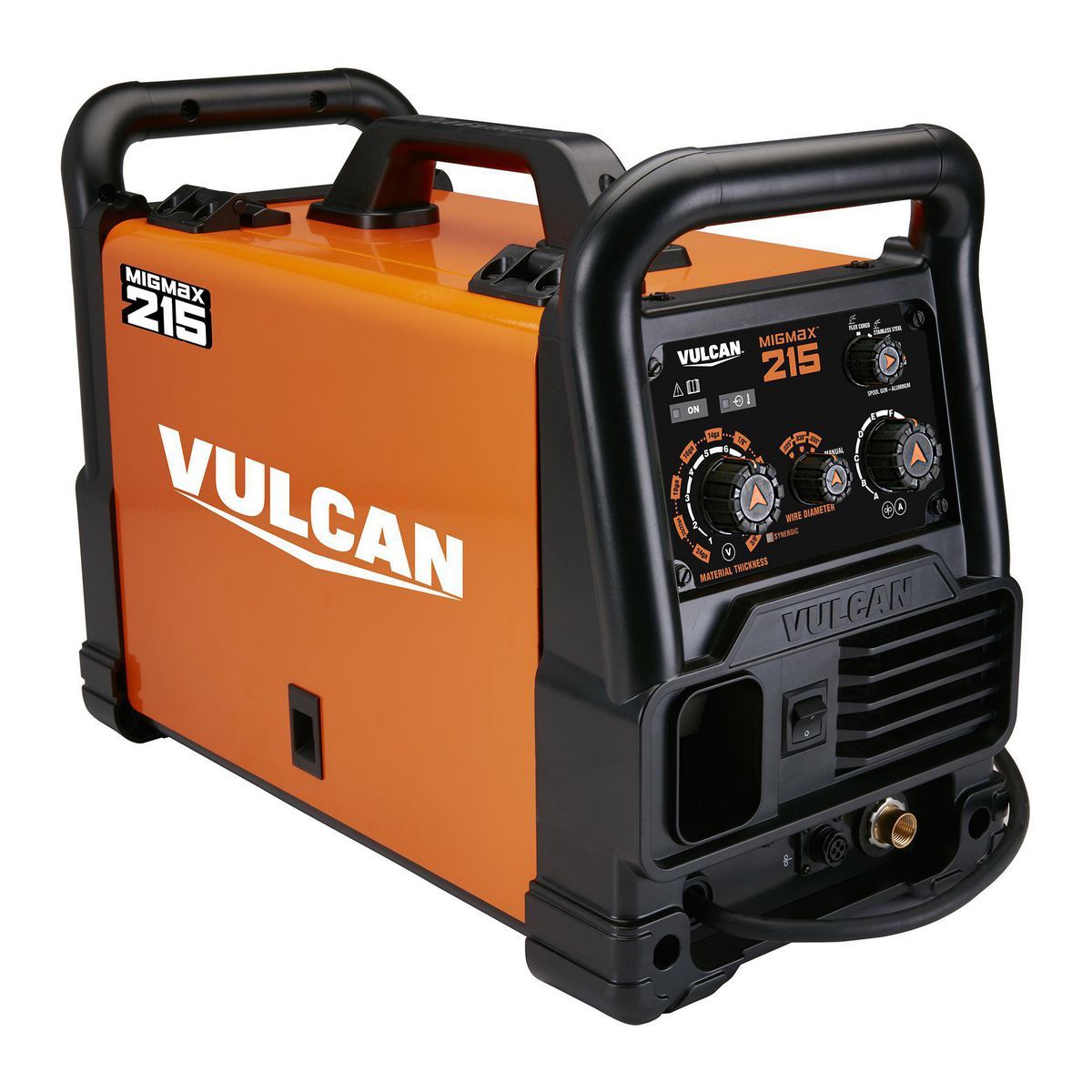

VULCAN MIGMax™ 215 Industrial Welder with 120/240V Input

- The VULCAN® MIGMax™ 215 Industrial Welder is a professional wire feed welder with a full synergic interface for trouble-free weld program setting. Just select the process, the wire diameter, and the material thickness – the welder does the rest. The industrial grade cast aluminum drive system easily feeds solid and flux core wire up to 15 ft. and can be set up without tools. The MIGMax 215 is spool-gun ready for welding aluminum (spool gun sold separately). Dual voltage 120V/240V input with an auto-sense feature gives you the flexibility to weld anywhere you want, whenever you want.

- Advanced synergic feature machine sets parameters automatically

- Advanced arc starting technology for smooth, spatter-free starts

- Tool free design for easy process or wire changeover

- Weighs only 44.00 lb. – ideal for shop or field use

- Dual voltage technology capable of 120V or 240V input

- Spool gun ready – no adapter required

- Industrial grade cast aluminum drive system

- Inverter technology for highest quality output and maximum efficiency

- 120V and 240V power cords included

$879.99

Deciding if the Vulcan 215 is Right for You

If you’re in the market for a new welder, you may be wondering if the Vulcan 215 is the right choice. As an experienced welder, I’ve tested out my fair share of machines – and I can confidently say that the Vulcan 215 is one of the best MIG welders currently available for hobbyists and professionals alike.

In this comprehensive buying guide, I’ll walk through everything you need to know about the Vulcan 215, from its top features and capabilities to proper set-up, maintenance, and more. I’ll also offer tips on accessories, compare it to other models, and provide advice to help you determine if the Vulcan 215 is the perfect welder for your needs and skill level.

An Overview of the Vulcan 215’s Benefits

The Vulcan 215 is a powerful, versatile 220V MIG welder made by Everlast. It’s ideal for home garage use, auto body work, fabrication projects, and maintenance/repair applications. Here’s a quick rundown of some of its top benefits:

- Welds up to 3/8″ mild steel – With its max 225 amp output, the Vulcan 215 can handle materials up to 3/8″ thick, making it suitable for most DIY and home shop welding tasks.

- Superior arc performance – The Vulcan 215 produces an extremely smooth, stable arc that allows for great control and easier welding, even for beginners.

- Spool gun capabilities – This machine can run a spool gun for aluminum welding (with the right torch), making it much more versatile than standard MIG welders.

- Dual voltage capacity – The Vulcan 215 can run on either 120V or 240V power, providing flexibility for use with different outlets.

- Portability – At just 38 pounds, the Vulcan 215 is lightweight and easy to move around the shop or transport to welding jobs.

- Affordability – Given its impressive features and performance, the Vulcan 215 provides incredible value at a very reasonable price point.

For hobbyists, DIYers, and professionals looking for an advanced MIG welder that won’t break the bank, the Vulcan 215 hits the sweet spot. Keep reading for an in-depth guide on how to use this machine and determine if it’s the right pick for your needs.

How to Set Up the Vulcan 215

One of the nice things about the Vulcan 215 is that it’s designed to be user-friendly right out of the box. But there are still some important steps you should take when first setting up your new welder:

1. Select an appropriate location. Pick a spot that’s protected from the elements, has good ventilation, and is a safe distance from flammable objects. The location should also be near a proper power outlet – either 120V or 240V.

2. Install the front drive system. The Vulcan 215 has a dual-gear adjustable wire drive system. Install the drive assembly and thread the welding wire through it smoothly.

3. Attach ground clamp and torch. Secure the work clamp to your welding table or workpiece. Then insert the MIG gun into the euro connector and tighten.

4. Select voltage. Decide if you’ll run your Vulcan 215 on 120V or 240V power. Then set the voltage switch accordingly.

5. Adjust drive tension. The tension knob controls how much force is on the wire. Adjust so it can feed smoothly but doesn’t slip.

6. Set up gas supply. For gas-shielded MIG welding, attach a regulator and Ar/CO2 mix cylinder, then connect the gas hose.

7. Select wire speed and power. Your settings will vary based on material and wire size. Dial these in to your specific application.

With those basics covered, you’re ready to start dialing in your machine’s settings more precisely and laying down some weld beads!

Is the Vulcan 215 a Good Choice for Beginners?

If you’re new to welding, you may be wondering if the Vulcan 215 is beginner-friendly enough for you. The short answer: yes, absolutely! While a powerful unit, the Vulcan 215 is designed for easy operation – even if you’ve never welded before. Here are some of the factors that make it a great choice for new welders:

- Clear settings – The dial controls for wire speed and amperage output are intuitive and easy to adjust on the fly as you weld.

- Stable arc – The smooth arc this machine produces helps beginners learn to control the weld puddle and produce good beads.

- Reduced spatter – Thanks to the auto-compensating arc force control, hot restarts, and other features, spatter is minimal for a cleaner weld.

- Great torch control – The ergonomic torch included with the Vulcan 215 promotes excellent handling, allowing you to guide the arc with precision.

- Portability – At just 38 pounds, this lightweight welder can be easily maneuvered around the shop as you learn.

- Dual voltage capacity – You can run it on 120V power initially for reduced output, then switch to 240V whenever you’re ready for more amperage capacity.

The Vulcan 215 has all the hallmarks of an excellent beginner welding machine. With some practice using scrap metal, even a total novice can learn to lay down professional-looking welds with ease.

Top Features and Capabilities of the Vulcan 215

Now let’s dive into the specific features that make the Vulcan 215 such a versatile, high-performance MIG welder for the money:

- Powerful 200 amp MIG welder – With a max 225 amp output, it can weld mild steel up to 3/8″ thick. Great capability for a 120/240V unit.

- Smooth Lift Start TIG welding – Allows you to do basic TIG welding with the touch of a button using the MIG torch.

- Spool gun ready – Built-in plug allows you to connect a spool gun for aluminum MIG welding.

- Dual digital displays – Easy-to-read meters show voltage and amperage settings.

- Solid copper transformers – Provides clean power and arc stability compared to aluminum wound models.

- Adjustable postflow – Adds shielding gas after welding to protect the weld as it cools.

- Spot weld timer – Allows you to set a specific weld time from 0.1 to 10 seconds.

- Automatic thermal overload protection – Prevents overheating and extends machine life.

- 24 month warranty – Backed by Everlast’s reliable support should any issues arise.

For an affordable 120/240V MIG, the feature set on the Vulcan 215 is very impressive. It provides almost any customization you need for high quality welds in a variety of applications.

What Does a Vulcan 215 Welder Cost?

With its excellent performance capabilities, you may worry the Vulcan 215 comes with a high price tag. Fortunately, this exceptional MIG welder is very reasonably priced for the value. Here’s a look at its cost:

- MSRP from Everlast: $949

- Street prices: Around $850-$900 online or locally

- Additional startup costs:

- MIG pliers ($40)

- Welding helmet ($100)

- Work clamps ($50)

- Contact tips ($20)

So you’re looking at spending around $1,000-1,100 for the welder itself and some essential accessories to get set up.

Compared to other full-featured MIG welders with similar power and performance, this is an incredibly affordable price point. You get incredible bang-for-your-buck with the Vulcan 215 – there are professional welders costing two to three times as much!

For home garage use, small fabrication jobs, auto work, and general repairs, the Vulcan 215 gives you everything you need at a price that’s tough to beat. And you know it will pay for itself quickly with the projects and jobs it allows you to take on.

Where to Buy a Vulcan 215 Welder

While Vulcan welders are sold exclusively by Everlast, you have several options of where to purchase:

- Direct from Everlast – Order online and have the welder shipped directly from the manufacturer. Everlast provides great customer service too.

- Local welding supply shops – Many carry Everlast models, so call around to check stock and pricing. This allows you to see the unit in person.

- Home improvement stores – Some big chains like Home Depot or Lowes may carry this model in stores and/or online.

- Online welding retailers – Companies like Welders Supply sell the full Everlast product line and offer free shipping.

- Amazon – Amazon has the Vulcan 215 in stock for quick shipping if you have Prime. Often at the lowest prices.

I’d recommend checking multiple options to find your best price on the Vulcan 215 model you want. And don’t forget to account for any applicable taxes and shipping fees in your area.

Buying directly from Everlast can make sense if they’re running promotions with freebies or discounts. They also have great customer service if any warranty issues come up after purchase.

Capability to Weld Aluminum

One of the most versatile features of the Vulcan 215 is its capability to weld aluminum using an optional spool gun. This makes it stand out from many other welders in its class.

Rather than converting the Vulcan 215 to a dedicated aluminum welder, Everlast designed it to quickly switch between steel and aluminum:

- It has a built-in spool gun connection that accepts aftermarket spool guns like the Magnum Pro 100SG.

- To weld aluminum, you disconnect the MIG torch and install the spool gun. It uses separate wire feeding mechanics designed for soft aluminum wire.

- The amperage range (up to 200A on 240V) provides sufficient penetration and heat input for aluminum up to 1/4″ thickness.

- You’ll want to switch to 100% argon shielding gas and aluminum wire when running the spool gun.

With a spool gun, you get exceptional control and aluminum weld quality rivaling more expensive welders. Then swap back to the MIG torch with steel wire in a couple minutes to resume steel projects. This versatility makes the Vulcan 215 exceptionally useful for hobbyists, automotive work, fabrication, and maintenance/repair applications.

Key Benefits of Owning the Vulcan 215

As you can see so far in this guide, the Vulcan 215 packs an incredible set of features and capabilities into a very affordable MIG welder. Here are some of the main benefits you’ll enjoy with this machine:

Welding Versatility

- The Vulcan 215 has voltage and amperage capacity for 3/8″ steel, but also aluminum welding with a spool gun

- Weld a wide range of materials for auto work, fabrication, artwork, home projects, and repairs

Ease of Use

- Intuitive controls allow for a short learning curve even for beginner welders

- Smooth arc starts and welds with minimal spatter

- Dial in perfect settings easily with independent wire speed and voltage control

Portability

- Lightweight (just 38 pounds) and compact size increases mobility around shop

- Easy to load into truck for transportation to welding jobsites

- Dual voltage capability (120V/240V) allows use with different power sources

Affordability

- Packed with advanced features at a very reasonable price point

- Significant value compared to other welders with similar capabilities

- Fast payback through all the jobs and projects it allows you to take on

For most home garage welders and small shops, the Vulcan 215 hits the sweet spot of power, performance, portability, and price.

How the Vulcan 215 Compares to Other Welders

Everlast designed the Vulcan 215 to give hobbyists and home garage welders professional-level performance at an affordable price point. But how does it stack up against some of the other popular welder models out there? Here’s a look at a few key comparisons:

vs. Lincoln Electric Handy MIG:

- The Lincoln 210 maxes out at 120V/20A output, much lower capacity than the Vulcan 215’s 240V/30A max

- Handy MIG only rated for 24ga – 1/4″ steel, compared to 24ga – 3/8″ for the Vulcan

- But the Lincoln is much lighter (19lbs) and more portable for very small jobs

vs Millermatic 211:

- Nearly identical power and performance capabilities

- But the Millermatic 211 costs around $1600 – almost double the price of the Vulcan!

vs. Hobart Handler 210:

- The Handler 210 also maxes out on 240V, but at 28A vs Vulcan’s 30A

- Hobart rated for 24ga – 1/4″ steel while Vulcan can weld up to 3/8″ capacity

- Handler 210 more expensive at around $950-1100

The Vulcan 215 competes very favorably on power, performance, and value compared to these other MIG models in the same class. Unless you need ultra portability, it’s a superior option in my book.

Recommended Accessories for the Vulcan 215

To get the most out of your new Vulcan 215, I recommend adding a few key accessories:

- MIG pliers – For adjusting the weld nozzle and wire. Essential accessory.

- Welding helmet – Auto-darkening helmets provide protection and visibility. The Vulcan Optix helmets are top-notch.

- Welding jacket/gloves – Necessary for protection from sparks and heat. Leather jackets and mitt-style MIG welding gloves work best.

- Spool gun – For aluminum welding, a spool gun like the Magnum Pro 100SG is highly recommended.

- Foot pedal – Allows hands-free amperage control while welding. Highly useful option.

- Cart – A wheeled cart provides storage and mobility. The Everlast PowerArc and V2 are sturdy choices.

- Weld table – A good quality steel welding table helps position workpieces. I’d recommend at least 2×4 ft.

While not critical, these types of accessories will enhance your experience using the Vulcan 215 and let you take on more ambitious projects with ease. Buy them over time as your needs and skills grow.

Troubleshooting Common Vulcan 215 Problems

Like any welder, it’s possible you may occasionally run into an issue with your Vulcan 215. Here’s some basic troubleshooting tips for a few common problems:

Uneven weld quality

- Check MIG torch components are fully tightened

- Clean nozzle to ensure no obstructions

- Adjust drive tension so wire feeds smoothly

Weld spatter

- Reduce voltage setting slightly

- Ensure ground clamp is tightly secured to workpiece

- Check MIG gas flow is not too high

Arc too harsh/unstable

- Lower wire speed

- Clean metal surfaces and remove rust/coatings

- Check MIG torch consumables are in good condition

Feeding issues

- Check alignment of wire through drive rolls

- Adjust drive tension properly

- Replace worn drive rolls

Burnback in nozzle

- Keep steady hand motion during welding to prevent burnback

- Extend stickout length slightly

Following some basic troubleshooting steps like these will resolve most minor issues. But don’t hesitate to reach out to Everlast customer support for assistance as well.

Warranty and Customer Support

Everlast offers a solid 24-month warranty on the Vulcan 215 welder. This covers parts and labor on any defects in materials or workmanship. Normal wear items are excluded.

Make sure to register your warranty within 30 days of purchase. You simply fill out the online form with your info and receipt copy.

Everlast is known for great customer service and support after the sale. You can reach their welding techs and experts via:

- Phone support 7 days a week

- Email for any questions

- Online knowledge center with helpful welding articles and guides

- Active community forum to connect with other owners

Considering the affordable price, the 2-year Everlast warranty provides great peace of mind on the Vulcan 215. I’m very impressed with their post-purchase support too.

Maintaining the Vulcan 215 for Maximum Life

To keep your Vulcan 215 in peak welding condition for many years, be sure to follow these maintenance tips:

- Keep it clean – Regularly vacuum dust and dirt out of the interior using a soft brush. Clean spatter off the casing.

- Check consumables – Examine contact tips, nozzles, MIG torch liner, etc and replace as needed. Don’t operate with failing consumables.

- Inspect connections – Check all cords, plugs, and connections for damage. Repair or replace any degraded components.

- Change drive rollers – Replace when rollers become too worn and affect wire feed.

- Run fan periodically – Turn on the welder for 10 mins without welding 1-2 times per month to circulate air through cooling fan.

- Check shielding gas flow – Ensure gas is flowing smoothly from the regulator through the MIG torch.

- Follow duty cycle – Don’t exceed the recommended 30% duty cycle at max amps to avoid overheating.

Taking good care of your Vulcan 215 with regular maintenance will ensure it stays in top form and provides years of reliable service life at peak performance.

Power Requirements of the Vulcan 215

One advantage of the Vulcan 215 is its dual voltage capacity. This allows you to run it on either standard 120V household power or more powerful 240V circuits:

120V operation:

- Plugs into any standard 120V outlet like other appliances

- Limited to 20A max output in 120V mode

- Reduced output capacity but useful for light gauge sheet metal etc.

240V operation:

- Requires a 240V circuit – often 30A or 50A in home garages

- Can output max 225A on 240V for 3/8″ capacity

- 240V mode recommended for most welding tasks and materials

This versatility makes the Vulcan 215 easy to install in any home shop. For thicker steel welding, aluminum, or extended high-amperage use, a 240V hookup is recommended. But 120V is fine for light duty welding.

Always use proper extension cords – minimum 12 gauge for 120V, 10 gauge for 240V. And ensure your electrical circuit has the amperage capacity to handle the Vulcan 215’s power draw.

Safety Tips for Operating the Vulcan 215

While MIG welding is generally safe when proper precautions are taken, it’s important to operate your Vulcan 215 safely. Here are some key tips:

- Wear safety gear – Complete helmet, gloves, jacket, and footwear at all times while welding.

- Keep work area clear – Remove all flammable materials to prevent fires. Have a fire extinguisher nearby.

- Check for gas leaks – Ensure all gas connections are tight. Immediately turn off gas if leaks are detected.

- Ground workpiece – Securely attach ground clamp directly to the metal you’re welding for stability.

- Watch fumes – Welding fumes can be hazardous. Use a fume extractor and work in a well-ventilated area.

- Watch electrical cords – Don’t trip hazards or touch live parts. Ensure insulation is intact.

- Check condition – Perform visual inspections for any damaged or worn components before use.

- Disconnect from power – Unplug unit when not in use and allow it to fully cool before storage.

Following basic safety measures will help you prevent accidents and get the most from your Vulcan 215. Above all, use common sense – don’t operate without proper training.

Duty Cycle of the Vulcan 215

An important factor for any welder is its duty cycle – the length of time it can operate at its maximum rated output before needing to cool down. For the Vulcan 215, Everlast rates it for the following duty cycle:

- 30% at 225 Amps

- Can weld continuously for 3 minutes

- Requires 7 minutes of rest to cool

This duty cycle refers to the maximum 225 amp output when using 240V power. At lower amps, you can weld for longer continuously.

The 30% at max rating is on par with comparable MIG welders in this class. It provides a good balance for home shop use – enough capacity for most jobs without excessive downtime.

Be sure to adhere to the duty cycle and let your Vulcan 215 cool fully between welding sessions. Avoid running it at max amperage for extended periods to prevent overheating damage. A small portable fan can help accelerate cooling cycles.

Capacity for Different Metal Types and Thicknesses

The Vulcan 215 can weld or braze a wide variety of ferrous and non-ferrous metals thanks to its voltage control, amperage range, and spool gun capabilities. Here’s an overview:

Steel

- Max capacity of 3/8″ mild steel

- Can weld thinner gauge sheet metal down to 24 gauge

- Low hydrogen steel requires special wire, but doable

Stainless Steel

- Better for thinner gauges up to 1/4″ max

- Use 308L and 316L stainless steel wire

Aluminum

- 1/4″ max with optional spool gun

- 5356 and 4043 aluminum MIG wires work well

Other metals

- Low carbon steel, chrome alloy, nickel alloys

- Cast iron and copper – use silicon bronze filler rod

Overall, the Vulcan 215 handles any common welding or brazing task you’re likely to encounter around the home shop, in auto work, or basic fabrication and repair jobs. It’s got you covered for both ferrous and non-ferrous metals.

Reviews of the Vulcan 215

The Vulcan 215 rates very well in online reviews from both professionals and regular consumers. Here are some thoughts:

“This welder absolutely punches above its weight class. The price makes it an excellent value for anyone from beginners to pros.”

“I’m a hobbyist mechanic and wanted something I could use for auto repairs and occasional fabrication projects. The Vulcan 215 is perfect – easy to use but with enough power to handle the thicker steel on truck frames.”

“As a professional welder, I was skeptical of the price but gave the Vulcan 215 a shot anyway. I’m glad I did – it lays down incredibly clean welds on par with my other industrial machines.”

“The aluminum welding performance with a spool gun is amazing. I can’t believe they offer that capacity on a 120/240V MIG package at this price point.”

Overall, most reviewers mention great ease of use, smooth welds, and tons of power in a compact MIG package – all for an unbeatable value. Owners love the Vulcan 215 for its versatility across many welding projects.

Improving Your Skills with the Vulcan 215

One great thing about the Vulcan 215 is that it helps you improve your MIG welding skills faster, even as a beginner. Here are some tips to advance your technique quickly with this welder:

- Dial in settings – Take time to fine tune wire speed and voltage for the perfect weld. Mark ideal settings.

- Practice on scrap – Test settings and motions on scrap metal before welding actual projects.

- Watch torch angle – Aim for a steady 10-15° angle and consistent travel speed.

- Mind torch height – Maintain proper contact-tip-to-work distance. Usually 5/8″ to 3/4″ is ideal.

- Use a smaller nozzle – Upgrades like a .030″ nozzle can increase weld precision.

- Try weaving – Once you master straight beads, try weaving for smoother, wider welds.

- Take a class – Consider a weekend welding class to sharpen skills with an expert instructor.

With consistent practice, the Vulcan 215 helps both experienced and inexperienced welders hone their technique. You’ll be laying down gorgeous welds in no time!

Storing the Vulcan 215 Properly

Proper storage and maintenance is key to ensuring your Vulcan 215 enjoys maximum lifespan. Here are some storage tips:

- Store in clean, dry location when not in use

- Allow unit to fully cool before putting away

- Drain condensation in air compressor after use

- Disconnect from power and gas supply

- Retract MIG torch liner when not in use

- Cover machine with a welding blanket to keep dust out

- If long-term storage, place desiccant packs inside unit

- Avoid extreme cold, heat, or humidity

By finding it a home in your shop where it’s protected from the elements, your Vulcan 215 will always be ready for your next welding task. With basic care, this quality machine will last many years and deliver an excellent return on investment.

Conclusion: An Exceptional MIG Welder for the Money

In the world of welders, it’s rare to find professional-level features, performance, and versatility at such an affordable price. But that’s exactly what you get with the Vulcan 215 from Everlast.

As you’ve seen in this comprehensive guide, the Vulcan 215 truly punishes above its class. It’s powerful enough to handle heavy-duty welding, but remains easy for anyone to use right out of the box. And it delivers exceptional quality welds in a huge range of materials unmatched at this price point.

For home DIYers, small fabrication shops, auto enthusiasts, artists, and other hobbyists, the Vulcan 215 is sure to become your go-to welder for years to come. It’s the perfect multi-process machine for most garage and small shop needs.

Thanks for taking the time to read this detailed buyer’s guide for the Vulcan 215. I hope it helps you determine if this is the right welder to fulfill your needs. Let me know if you have any other questions – I’m happy to help fellow welders find equipment that brings out their best work. Keep welding!